Formatting

transmitting tubes

and

associated questions

You

need to format or "burn in" old transmitting tubes that have been on

the shelf for some time in order to avoid arcing and the risk of

destroying them. You can find descriptions and procedures on how to do

this on several places on the Internet. SM5BSZ among others. This is my

way of dealing with this process.

I

use the old HAIR-rule: Heater - Anode - Idle - RF . Start with heater

voltage only, then apply anode voltage, after that run idle current in

the tube and finally apply RF to the tube. This rule has been

successfully used on many different tubes over the years; 4CX250B,

4CX350A, GS23b, TH308, TH328, TH338, YD1277 etc.

Formatting

process

Take

the

following steps in order to format transmitting tubes that have been on

the shelf for a long time:

- Run

the tube with heater voltage only for at least 24 hours. You may start

with lower heater voltage than specified for a few hours (may be

disputed due to the risk of poisoning the cathode). NOTE!

During this and all following operations, full cooling air flow shall

be applied to the tube, even to the cathode area as

specified/recommended by the tube manufacturer.

- Apply

then HV

to the tube with series resistor (SM6EHY recommends 100 k). I use

different resistors depending

on the tube. 33 kohm is a good start. Start with a low voltage, say 500

V and work your way up in 300 to 500 V increments until you have

reached the voltage level you will use in normal operation. Stay at

each level for half an hour to an hour. For tetrodes this step shall be

done without screen voltage applied.

- Connect

the high voltage line without the current limiting resistor to the

tube. For tetrodes also apply screen voltage, you may use a reduced

value (say 70 % of normal). Start again at 500 V anode voltage and

adjust the bias to a small anode current (say 50 mA). Let the tube run

for an hour. Increase the anode current to say 100 mA (depending on the

tube in question). Run for half an hour. Reduce the anode current to

zero again and increase the anode voltage by 300 to 500 V. Adjust the

bias for 50 mA anode current and run for half an hour. Increase the

anode current to 100 mA again. Continue this procedure until you are

close to your desired operating anode voltage. Increase the anode

current to a higher value and let the tube run. The anode of the tube shall be

warm. NOTE! DO NOT

touch the anode to check. Do not even think about it.

Measure the outlet air

temperature instead. The outlet air temperature shall increase

considerably, but

make sure you do not over heat the tube. I usually go up to 50 degrees

C of air outlet temperature. I measure the air outlet temperature by

the use of the outdoor sensor of a regular indoor/outdoor digital

thermometer.

- Decrease

the anode voltage again to a moderate value, say 60 % of the desired

operating voltage. Adjust the bias to a low but proper anode current.

Apply a small amount of RF, increasing the anode current slightly. Run

for a few minutes. Increase the RF drive somewhat to give an slightly

hinger anode current. The RF may be pulsed or why not send "TEST DE

YOUR CALL" in CW. Increase the anode voltage in moderate steps, say 100

to 200 V t a time and run for some time. Repeat until you are close to

your desired operating voltage. This may take a few hours to get there.

Monitor the outlet cooling air temperature again in order to have a

check on the anode

temperature. Keep it at about 50 deg C. Run the tube extensively at

this reduced power level on for instance local rag chaw QSO's for some

time, the more the better.

- You

should now be ready to run the tube at full data.

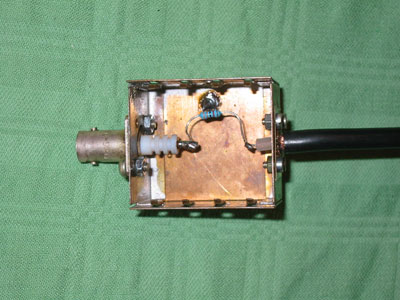

Limiting resistor box with MHV

connectors.

Limiting resistor box with MHV

connectors.

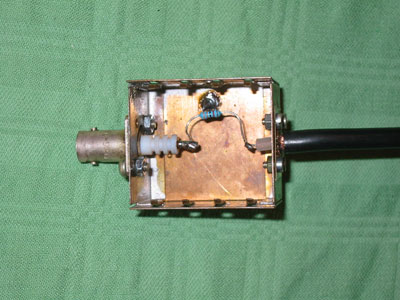

Inside the limiting resistor

box.

Inside the limiting resistor

box.

Post

formatting considerations

Even

after a well performed formatting process occasional arcing can occur

in a transmitting tube. Some people claim that a transmitting tube will

adopt to the actual working voltage and by that give occasional arcs

even at the normal operating voltage. I have not been able to confirm

this thesis, but some unexpected arcs may be explained by this idea. In

order to limit the consequences from such an arc some precaution can

be taken.

I have had arcing several times in different types

of tubes and PA's but have not yet had one tube destroyed from the

arcing. The three phase high voltage power supply I am using has about

10 uF capacitance and an transformer capable of delivering

>4.5 kVA (about 45 kg of iron). Fuses on both the incoming three

phase (3 x 400 V) and on the outgoing high voltage line. The incoming

fuses have never opened up, but that have the fuses on the high voltage

line. In the high voltage line is also a low inductance current

limiting resistor of

100 ohm with a power rating of 100 W.

It seams like if you have a current limiting series

resistor and well fused you can limit the devastation from an arc in

the transmitter tube.

Heater

voltage considerations

A

transmitter tube is sensitive to the applied heater voltage. You

should always follow the recommendations of the manufacturer closely.

Running a tube on a too high heater voltage will shorten the life of

the tube. Running the tube on a too low heater voltage can poisoning

the cathode. This is especially true for the Thoriated Tungsten cathode

type.

Running a transmitting tube on UHF close to it's upper

frequency limit

may cause back-heating of the control grid and by that emission from

the grid. This can be harmful to the tube. In order to avoid

back-heating you can slightly lower the heater voltage. Many

manufacturer of tubes have clear recommendations of how much to lower

the heater voltage.

One way of finding the optimum heater voltage for a tube is

to run the

tube with a standing current (I.E. Ia =100 mA) and vary the heater

voltage while monitoring the change of the standing current. You will

find that the standing current will vary with the heater voltage in an

non-linear way. By finding the "knee voltage" and using a heater

voltage just above the knee you will get the most operating time out of

the

tube without sacrifice performance.

It is an good idea to limit the rush-in current when applying

heater

voltage to a cold tube. Connect a series resistor on the primary side

of your heater transformer and short it out after 5 to 10 seconds of

heater time. Using a variable resistor in the primary circuit of the

heater transformer gives the possibility to adjust the heater voltage.

If the heater transformer is used for generating other voltages as well

it may not be possible to vary the resistance in the primary circuit.

In this case you need to have the resistors in the secondary circuit of

the heater transformer. Always let the tube pre-heat the specified time

before applying anode current and RF to the tube.

A too high heater voltage can induce arcing in the tube. This

may be a

effect of back-heating.

Transmitter

tube cooling considerations

Adequate

cooling of a transmitting tube is essential. Always follow the

manufactures recommendations about the required amount of cooling air.

More cooling air than recommended is just fine. But, how to know how

much fan is enough?

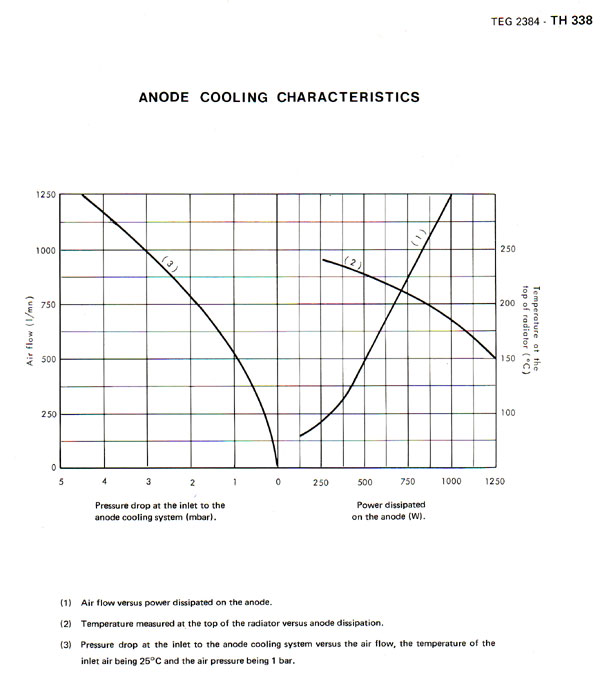

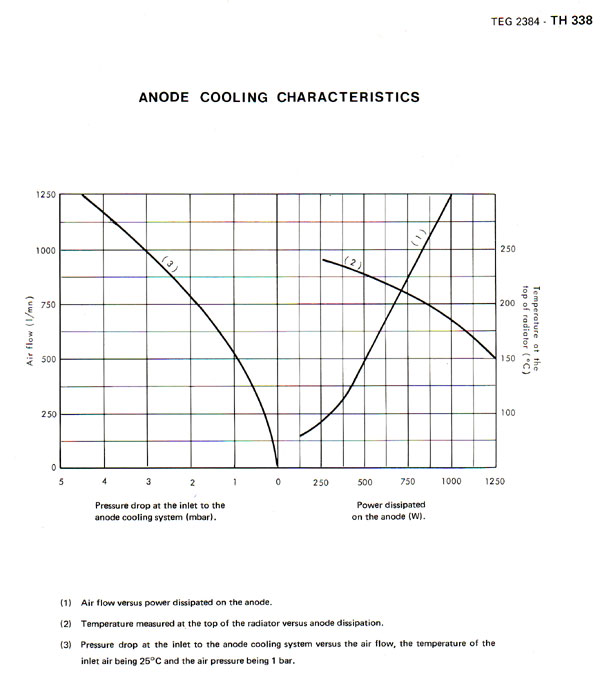

In the data sheet of many transmitting tubes you can find

graphs on

back pressure versus air flow as well as dissipated power. The same can

be found on many fans. By checking these against each other you can

find out if the fan is enough for the application.

There

are three major fan types; radial, diagonal and axial. The radial fans

have a 90 degree angle between air inlet and outlet and gives in

general the best back pressure. The axial fans have a 0 degree angle

between air inlet and outlet and does not give a high back pressure.

The diagonal fan have

a 0 degree angle between air inlet and outlet but a different angle on

the rotor blades compared to the axial fan. The diagonal fan gives in

general a better back pressure than the axial fan.

It is also very easy to measure back pressure by using a non

opaque

plastic tube. Form the plastic tube to a U-shape and mount it on a

stand. Fill the U with water so you get the two water surfaces at a

convenient hight. Attach one end of the plastic tube to the high

pressure side of the tube. Measure the hight difference of the two

water surfaces. This measure in mm is the back pressure in mmVp.

You

can find many different units for both back pressure and air flow and

it is not always easy to convert between them. Here is a small guide to

these conversions:

10 mmVp = 1 mbar = 100 Pa = 0.39 inches of water

1 m3/min = 60 m3/h

= 1000 l/min = 35.3 cfm

For

my 23 cm PA I am using the below combination of fan and tube. For 12 V

of fan voltage (at low speed dashed curves) I measure 15 mmVp that

corresponds to an air flow of 150 m3/h and at 11

V (full speed solid curve) 28 mmVp corresponding to ~200 m3/h.

Air flow

versus back pressure for Bosch BPA 12 V radial fan (part number 0 130

007 804)

Air flow

versus back pressure for Bosch BPA 12 V radial fan (part number 0 130

007 804)

Air

flow versus back pressure for Thompson TH338 triode

Air

flow versus back pressure for Thompson TH338 triode

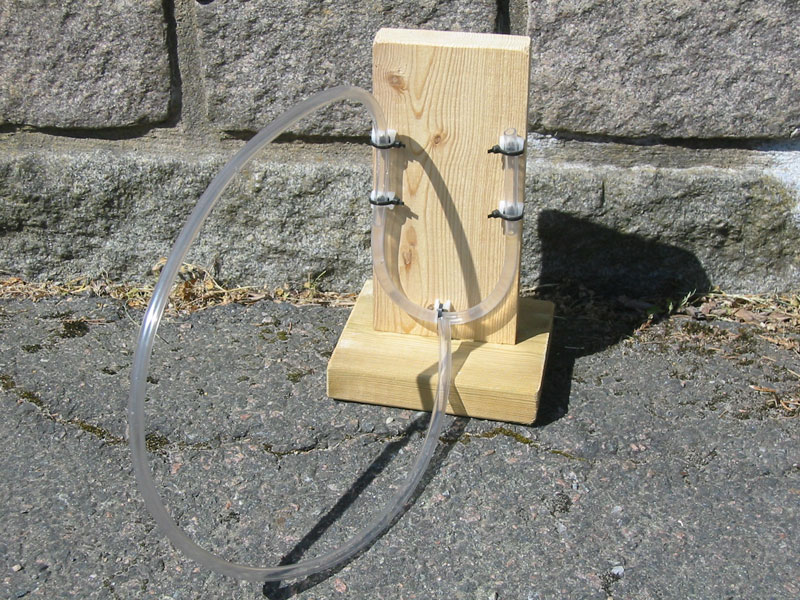

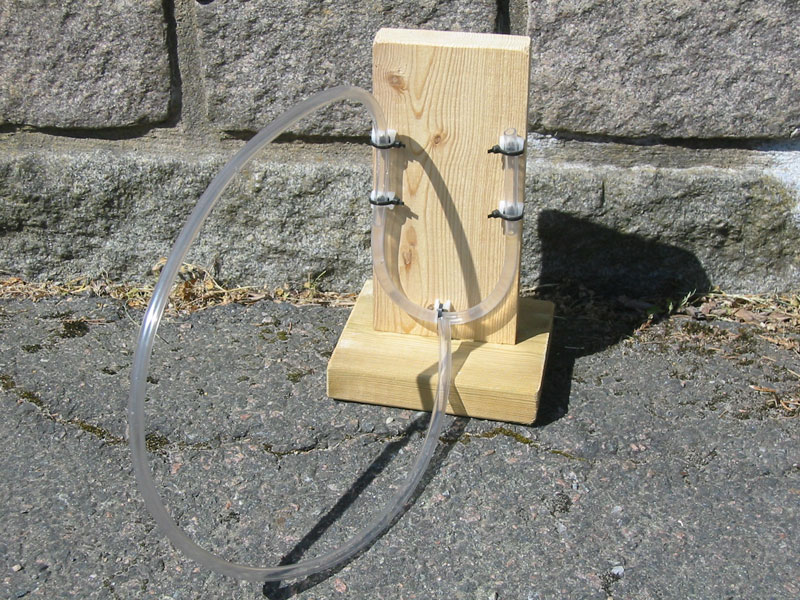

A

simple way of measuring back pressure is to use this back

pressure gauge. It uses physical constants to measure the back pressure

and is by this self calibrating.

Back

pressure gauge

Back

pressure gauge

Connect

the end of the plastic tube of the back pressure gauge to the back

pressure test outlet of the pressurized anode compartment and read the

difference between the two water surfaces with the fan running. This is

the back pressure in mmVp or in inches of water if you prefer that.

Back

pressure test outlet

Back

pressure test outlet

Links

SM5BSZ

home page: http://www.sm5bsz.com/

About tubes / valves

in general: http://www.thevalvepage.com/index.shtml

About "getters": http://www.thevalvepage.com/valvetek/getter/getter.htm

References:

[1]

Care and feeding of POWER GRID TUBES, Laboratory staff , Varian,

Eimac Division, 1967, Library of Congress No. 67-30070

Updated July 27th, 2009.

http://www.2ingandlin.se/SM6FHZ.htm

Air flow

versus back pressure for Bosch BPA 12 V radial fan (part number 0 130

007 804)

Air flow

versus back pressure for Bosch BPA 12 V radial fan (part number 0 130

007 804) Air

flow versus back pressure for Thompson TH338 triode

Air

flow versus back pressure for Thompson TH338 triode Back

pressure gauge

Back

pressure gauge Back

pressure test outlet

Back

pressure test outlet